I abandoned the electric box when UPS arrived with a package. I had had an email to advise me that a delivery from Moto Lita was on its way, bang on time at just over four weeks from confirming the order.

My first fear was, had my B&G quick release boss been included in the package and of course it had. The four spoke wheel was superb and the screw holes matched those in the top half of the quick release boss, the finishing touch was the 'Morgan' engraved central boss that would cover the screw heads.

Something was wrong though, the hole in the boss wasn't splined and just wobbled about on the end of the steering column, a call to B&G racing told me that 'I needed a hub fitting kit' silly me!, but I was stumped when I was asked what car it was for, I told him I would call back. An email to Arthur was partway helpful, the column came from Westfield cars and was old British standard, to dot the i's, I measured the diameter of the spline, 18.5mm and counted the number of splines, approx 46. The next day I called B&G and with the above info they identified the kit and it arrived the next day, problem solved.

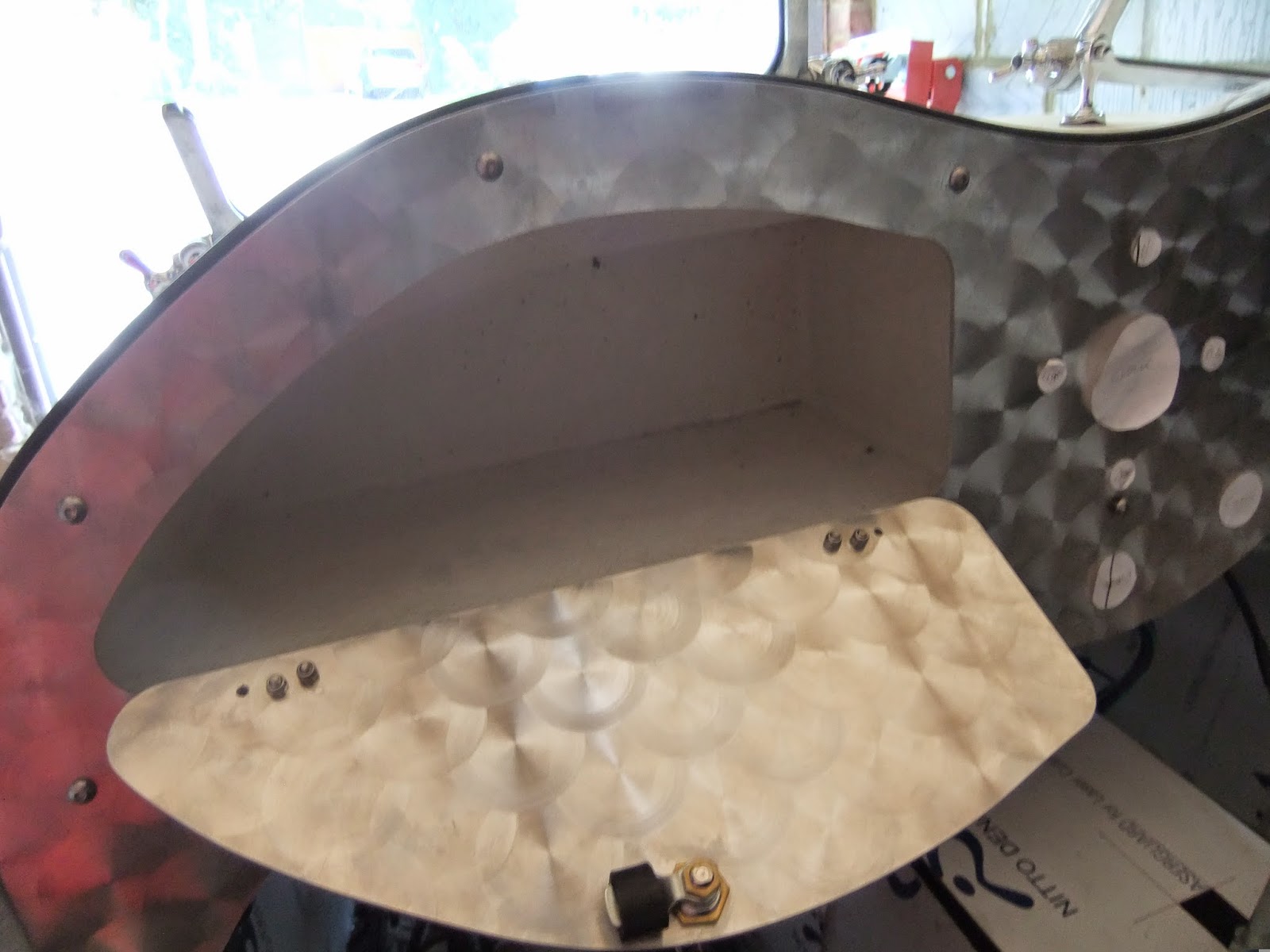

One slight problem remained, the Hub had a protruding ring which was intended for a steering wheel to sit over, but the base plate of the Q/R boss needed to sit flush, I carefully hack sawed off the ring and filed the top smooth, the above photo shows the sawn off ring and the abraded top of the boss, but this will be covered by the plate, so not a problem. The wheel is removed by pulling upwards on small paddles that protrude either side of the boss and simultaneously pushing in a small button, this is a two handed job and definitely cannot be accidentally done whilst driving. the boss is very securely located by a series of large ball bearings which eliminate any sloppiness or backlash.

It all fitted together very easily, although I haven't actually bolted the hub onto the steering column yet, as it will have to come off to allow the dashboard to be removed. The photo immediately above shows what is left when the wheel is detached and you might well be asking, why I feel the need to remove the steering wheel at all, the reason is that it would be a tight squeeze sliding my long legs under the dash with the wheel in place. Even Morgan now fit detachable steering wheels to their production cars. I am pleased that I decided not to cut any holes in the dash until the wheel was in place, because it is evident, without yet sitting in the car, that some instruments/switches are obstructed by the spokes, so a little adjustment is required before I start cutting and drilling

.JPG)