At last I have removed 99% of the wiring loom from my donor Moto Guzzi, only the rectifier and wiring to rear light cluster remain in place. It don't look much, but it was a bit like removing the entrails from a carcass, not something that I have ever done, so it's probably nothing like it at all, but it was all entwined around the frame.

There it is lying on the garage floor along with the clutch cable and instruments, I hope with all necessary labels still attached, which will help me to eventually instal it in the car.

I imagine that there will be plenty of shortening and lengthening of the cables to get it to fit neatly, but as long as I rejoin pink to pink etc. fingers crossed there shouldn't be to many faults.

Saturday, 30 November 2013

Monday, 18 November 2013

OF COLLETS AND COLLARS

Ooh, I have two followers now, it's good to know that my kitcar adventure maybe of interest to others. I have also had a 'comment' on my last post, from Peter, I have had a look at the pics of his finished car and it is superb, I only hope that when I eventually finish mine it looks half as good.

I took advantage of a dry, bright morning to set up my workmate in the front of the garage to take advantage of good light. Carefully using sharp chisels I removed the firmly stuck cylinder/base gasket, it is important to keep the blade absolutely flat to the surface to prevent scoring and eventually all trace was removed.

Next job was to remove the valves from the heads. I have a choice of three valve spring compressors and it was my old standard black one that did the job. Initially the springs wouldn't compress as the split collets were stuck in the collars, a small socket placed over the top of the valve stem and an extension bar, when tapped with a mallet unstuck the collets and the valves removed. Everything was washed off with paraffin, dried and again carefully stored in the correct order..

The fourteen allen headed screws, not forgetting the four bolts that held the sump pan to the crankcase, were removed and the pan dropped down. I had remembered to drain the oil first, always a messy job, but it didn't take too much mopping up afterwards. The oil filter was removed and the pan then washed with paraffin and dried. The next day it was all packed up and along with the carbs, it was delivered to Dave at TSR Vapour Blasting at Sevenoaks, who said it should all be ready for collection in a week.

I took advantage of a dry, bright morning to set up my workmate in the front of the garage to take advantage of good light. Carefully using sharp chisels I removed the firmly stuck cylinder/base gasket, it is important to keep the blade absolutely flat to the surface to prevent scoring and eventually all trace was removed.

Next job was to remove the valves from the heads. I have a choice of three valve spring compressors and it was my old standard black one that did the job. Initially the springs wouldn't compress as the split collets were stuck in the collars, a small socket placed over the top of the valve stem and an extension bar, when tapped with a mallet unstuck the collets and the valves removed. Everything was washed off with paraffin, dried and again carefully stored in the correct order..

The fourteen allen headed screws, not forgetting the four bolts that held the sump pan to the crankcase, were removed and the pan dropped down. I had remembered to drain the oil first, always a messy job, but it didn't take too much mopping up afterwards. The oil filter was removed and the pan then washed with paraffin and dried. The next day it was all packed up and along with the carbs, it was delivered to Dave at TSR Vapour Blasting at Sevenoaks, who said it should all be ready for collection in a week.

In the meantime I visited Corsa Italiana at Walton on Thames and returned with a full set of gaskets. a smart set of conical air filters for the carbs and smart braided oil lines to replace the tatty ones between timing cover and heads. I also ordered a polished aluminium alternator cover. I can't wait to start putting it all back together.

Monday, 11 November 2013

TOPS OFF

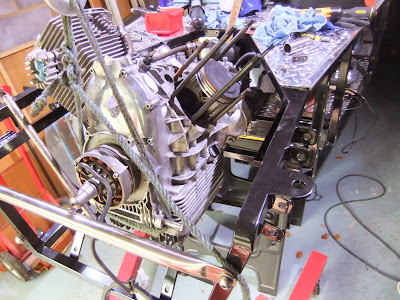

I feel that on this posting I will more than make up for not having my camera available for the last one. Firstly there follows a couple of pics showing off the shiny crankcase and gearbox.

Now it was time to remove the heads and cylinders and the first difficulty appeared, the side chassis rails fouled access to the spark plugs and it would be necessary to remove these to get at one of the head nuts that lay beneath the spark plug. On the left side I could just slide in the plug socket and using the 1/2 in drive with a spanner I was able to loosen and then remove the plug. On the right side this wasn't possible and the engine would have to be tilted up at the front to access the plug.

A socket applied to the alternator securing nut allowed me to turn the

engine over so that the relevant valves were in the closed position before loosening the head nuts.

I could now remove all the head nuts on the left side, one of which was an allen key headed nut that was hidden under a really tight cap, both of which took some serious shifting.

The rocker gear and push rods were lifted out and placed in an orderly manner on my bench. I decided to loosen all the accessible nuts on the right side before tilting the engine, so that I could safely use maximum leverage on the stubborn nuts. The engine crane was again deployed and with the weight of the engine taken, the front bolt was removed and the engine tilted just enough to remove the plug and nut from the right side. When it was time to lift off both heads and cylinders I realised that if I hadn't have tilted the engine I would not have been able to have got them off as they would also have fouled the chassis side rails, all worked out well in the end.

These items were laid out on my work bench, to await valve removal and de-oiling, but on initial inspection,the inside of the cylinders and the pistons looked to be score free and in good health.

With both pistons now exposed the engine was then gently lowered and re secured in the chassis. Next job is to drain the oil from the sump and then remove the sump cover, which will, along with the heads, cylinders and carbs be taken for professional cleaning, but that's enough for today.

Now it was time to remove the heads and cylinders and the first difficulty appeared, the side chassis rails fouled access to the spark plugs and it would be necessary to remove these to get at one of the head nuts that lay beneath the spark plug. On the left side I could just slide in the plug socket and using the 1/2 in drive with a spanner I was able to loosen and then remove the plug. On the right side this wasn't possible and the engine would have to be tilted up at the front to access the plug.

I could now remove all the head nuts on the left side, one of which was an allen key headed nut that was hidden under a really tight cap, both of which took some serious shifting.

The rocker gear and push rods were lifted out and placed in an orderly manner on my bench. I decided to loosen all the accessible nuts on the right side before tilting the engine, so that I could safely use maximum leverage on the stubborn nuts. The engine crane was again deployed and with the weight of the engine taken, the front bolt was removed and the engine tilted just enough to remove the plug and nut from the right side. When it was time to lift off both heads and cylinders I realised that if I hadn't have tilted the engine I would not have been able to have got them off as they would also have fouled the chassis side rails, all worked out well in the end.

These items were laid out on my work bench, to await valve removal and de-oiling, but on initial inspection,the inside of the cylinders and the pistons looked to be score free and in good health.

With both pistons now exposed the engine was then gently lowered and re secured in the chassis. Next job is to drain the oil from the sump and then remove the sump cover, which will, along with the heads, cylinders and carbs be taken for professional cleaning, but that's enough for today.

Saturday, 9 November 2013

THE SHINING 2

I'm useless! In my keenness to get out to the garage and get to work I keep forgetting to take the camera, so apologises no photos of this bit.

I decided it was time to clean up the crankcase and gearbox and the best way to do this was to haul the engine out off the chassis and rest it on my workmate. I plugged all the open orifices to prevent dirt getting into the engine and went to work with my electric drill, driven assortment of wire brushes, within a few hours work the old bubbled paint and crud was removed. My Dremel, with a variety of small brushes got into all of the nooks and crannies and I now have a shiny engine.

I lifted the engine down to ground level and liberally sprayed it with water soluble de-greaser which I brushed vigorously before hosing it off. I dried the engine using the compressor air line and then lifted it back into the chassis. My £130 engine lift is definitely proving to be one of my better cheap purchases.

I will soon remove the heads, cylinders, and sump and together with the carbs I will take them to www.tsrvapourblasting.co.uk in Sevenoaks, for cleaning. They recommend, ACF-50 a compound which is used in the aviation industry to prevent corrosion, this is apparently ideal for keeping that just blasted look on aluminium cases and I will be using this to hopefully keep the engine sparkling.

I decided it was time to clean up the crankcase and gearbox and the best way to do this was to haul the engine out off the chassis and rest it on my workmate. I plugged all the open orifices to prevent dirt getting into the engine and went to work with my electric drill, driven assortment of wire brushes, within a few hours work the old bubbled paint and crud was removed. My Dremel, with a variety of small brushes got into all of the nooks and crannies and I now have a shiny engine.

I lifted the engine down to ground level and liberally sprayed it with water soluble de-greaser which I brushed vigorously before hosing it off. I dried the engine using the compressor air line and then lifted it back into the chassis. My £130 engine lift is definitely proving to be one of my better cheap purchases.

I will soon remove the heads, cylinders, and sump and together with the carbs I will take them to www.tsrvapourblasting.co.uk in Sevenoaks, for cleaning. They recommend, ACF-50 a compound which is used in the aviation industry to prevent corrosion, this is apparently ideal for keeping that just blasted look on aluminium cases and I will be using this to hopefully keep the engine sparkling.

Subscribe to:

Posts (Atom)