Not much inducement to get out into the cold damp garage at the moment, but there were a couple of jobs I wanted to get done before Christmas.

The rubber bobbins, I had got from EBay, for mounting the coil pack were in danger of getting lost, so I thought it wise to decide the best place for them and get the job done, only four holes to drill, didn't take long, just had to ensure the coils cleared the closed bonnet and that the HT leads had an unobstructed run to the plugs.

In lieu of anything else important to do I ordered a pair of Aero Screens, Brooklands style. £55 each, excellent, although the aluminium frames will need a bit more polishing, but as you probably know by now, I like polishing. I took my time in measuring and marking where the holes for the support brackets needed to be and then drilled them using a 4.5m drill for the 4ba bolts which would allow a little wriggling room for alignment. I made up four brass backing plates out of an old letter box internal flap, to spread the load on the underside of the scuttle. Job done, starting to look the biz.

Hopefully the New Year will bring forth steering and suspension parts from Arthur and allow me to move things on, in the meantime I will make a start on sorting out the wiring loom.

Merry Christmas and a Happy New Year to anybody out there who happens to have nothing better to do than read my little blog.

Sunday, 22 December 2013

Friday, 6 December 2013

FINISHED WITH ENGINE

Tappets have been adjusted, 0.15 mm for exhaust and 0.10mm for inlet, the socket on the alternator nut allowed me to turn the engine over so that each piston was at TDC on the firing stroke, thus ensuring that the pushrods were at their lowest position before the feeler gauge was introduced between the tappet and the valve stem.

The remains of the, well and truly stuck on, gasket was removed from the underside of the rocker covers. New gaskets were in place and the covers were bolted back on, after another quick polish.

Whilst I was unscrewing the second of the two screws on top of the left hand carb, in preparation to reconnecting the throttle cable, I failed to hold down the top and like a jack in the box, as the last thread of the screw released the top and spring sprung out. The spring I found on the floor on the other side of the garage, but the top totally dissapeared. I assumed it must have gone even further than the spring, but despite fruitlessly turning the garage inside out I gave up looking for it and set about connecting the other carb, ensuring that I held the top down. All went well and as I adjusting the cable, there was the other top, not more than four inches away tucked down between the two cylinders, what a relief.

The throttle cable was soon connected to that carb and then the whole lot was liberally sprayed with the ACF-50 anti corrosion spray, just going to leave it now for the spray to creep into all the nooks and cranies before wiping off the excess. I have to say that I am very pleased with the finished appearance of the engine. Smug Git

One last thing, I have resolved my problem with getting a plug socket passed the chassis side rail and onto the spark plugs, a new 3/8 drive one just slips in and an adjustable wrench on the hex end of the socket allowed me to tighten the plugs.

The remains of the, well and truly stuck on, gasket was removed from the underside of the rocker covers. New gaskets were in place and the covers were bolted back on, after another quick polish.

Whilst I was unscrewing the second of the two screws on top of the left hand carb, in preparation to reconnecting the throttle cable, I failed to hold down the top and like a jack in the box, as the last thread of the screw released the top and spring sprung out. The spring I found on the floor on the other side of the garage, but the top totally dissapeared. I assumed it must have gone even further than the spring, but despite fruitlessly turning the garage inside out I gave up looking for it and set about connecting the other carb, ensuring that I held the top down. All went well and as I adjusting the cable, there was the other top, not more than four inches away tucked down between the two cylinders, what a relief.

The throttle cable was soon connected to that carb and then the whole lot was liberally sprayed with the ACF-50 anti corrosion spray, just going to leave it now for the spray to creep into all the nooks and cranies before wiping off the excess. I have to say that I am very pleased with the finished appearance of the engine. Smug Git

One last thing, I have resolved my problem with getting a plug socket passed the chassis side rail and onto the spark plugs, a new 3/8 drive one just slips in and an adjustable wrench on the hex end of the socket allowed me to tighten the plugs.

Monday, 2 December 2013

TOPS ON

Last Wednesday I collected my bits from Dave at www.tsrvapourblasting.co.uk and I wasn't disappointed. Shiny bright, thanks Dave. He assures me that the carbs have been reset to pre. dissasembly setting since emerging from the ultra-sonic bath, but may need slight adjustment once engine is running.

The photos show the newly cleaned parts, plus the new carb filters, oil line to rockers and polished ali alternator cover. Time to put it all back together again. First on was the sump pan, not forgetting the new oil filter and then the laborious task of valve grinding, thankfully only four valves.

Valves were reinstalled using my trusty old valve spring compressor and plenty of oil down the valve guides.

I have plenty of piston ring compressors, ranging from small, which must have been for my first Villiers powered 2 stroke motor bike, up to a big bugger which was probably for my AJS 500cc single, anyway it has marked on it 2/6d so I have had it a long time. A slightly longer screw to hold it together and it slipped over these 530cc pistons a treat. The weight of the cylinder sliding down the studs was sufficient to push the compressor to the bottom of the piston where I unscrewed the clamping screw and gently pulled the compressor out around the studs. Off course I had to raise the engine to give clearance for the cylinders and heads to drop into place, but it all went very smoothly.

Fortunately I had not forgotten the two O rings which go over the top and bottom studs before the cylinders are dropped on, and then the other 4 O rings are placed over the other studs before the rocker cradle is postioned over them and the whole lot is bolted down to 30psi, that was after the engine was lowered and secured in the chassis.

I oiled the ends of the push rods and located them down their respective shafts before the rocker gear was installed, again using a liberal amount of oil over the securing pins. Just remains to adjust the tappets and refit the rocker covers.

The photos show the newly cleaned parts, plus the new carb filters, oil line to rockers and polished ali alternator cover. Time to put it all back together again. First on was the sump pan, not forgetting the new oil filter and then the laborious task of valve grinding, thankfully only four valves.

Valves were reinstalled using my trusty old valve spring compressor and plenty of oil down the valve guides.

I have plenty of piston ring compressors, ranging from small, which must have been for my first Villiers powered 2 stroke motor bike, up to a big bugger which was probably for my AJS 500cc single, anyway it has marked on it 2/6d so I have had it a long time. A slightly longer screw to hold it together and it slipped over these 530cc pistons a treat. The weight of the cylinder sliding down the studs was sufficient to push the compressor to the bottom of the piston where I unscrewed the clamping screw and gently pulled the compressor out around the studs. Off course I had to raise the engine to give clearance for the cylinders and heads to drop into place, but it all went very smoothly.

Fortunately I had not forgotten the two O rings which go over the top and bottom studs before the cylinders are dropped on, and then the other 4 O rings are placed over the other studs before the rocker cradle is postioned over them and the whole lot is bolted down to 30psi, that was after the engine was lowered and secured in the chassis.

Saturday, 30 November 2013

LOOMING LARGE

At last I have removed 99% of the wiring loom from my donor Moto Guzzi, only the rectifier and wiring to rear light cluster remain in place. It don't look much, but it was a bit like removing the entrails from a carcass, not something that I have ever done, so it's probably nothing like it at all, but it was all entwined around the frame.

There it is lying on the garage floor along with the clutch cable and instruments, I hope with all necessary labels still attached, which will help me to eventually instal it in the car.

I imagine that there will be plenty of shortening and lengthening of the cables to get it to fit neatly, but as long as I rejoin pink to pink etc. fingers crossed there shouldn't be to many faults.

There it is lying on the garage floor along with the clutch cable and instruments, I hope with all necessary labels still attached, which will help me to eventually instal it in the car.

I imagine that there will be plenty of shortening and lengthening of the cables to get it to fit neatly, but as long as I rejoin pink to pink etc. fingers crossed there shouldn't be to many faults.

Monday, 18 November 2013

OF COLLETS AND COLLARS

Ooh, I have two followers now, it's good to know that my kitcar adventure maybe of interest to others. I have also had a 'comment' on my last post, from Peter, I have had a look at the pics of his finished car and it is superb, I only hope that when I eventually finish mine it looks half as good.

I took advantage of a dry, bright morning to set up my workmate in the front of the garage to take advantage of good light. Carefully using sharp chisels I removed the firmly stuck cylinder/base gasket, it is important to keep the blade absolutely flat to the surface to prevent scoring and eventually all trace was removed.

Next job was to remove the valves from the heads. I have a choice of three valve spring compressors and it was my old standard black one that did the job. Initially the springs wouldn't compress as the split collets were stuck in the collars, a small socket placed over the top of the valve stem and an extension bar, when tapped with a mallet unstuck the collets and the valves removed. Everything was washed off with paraffin, dried and again carefully stored in the correct order..

The fourteen allen headed screws, not forgetting the four bolts that held the sump pan to the crankcase, were removed and the pan dropped down. I had remembered to drain the oil first, always a messy job, but it didn't take too much mopping up afterwards. The oil filter was removed and the pan then washed with paraffin and dried. The next day it was all packed up and along with the carbs, it was delivered to Dave at TSR Vapour Blasting at Sevenoaks, who said it should all be ready for collection in a week.

I took advantage of a dry, bright morning to set up my workmate in the front of the garage to take advantage of good light. Carefully using sharp chisels I removed the firmly stuck cylinder/base gasket, it is important to keep the blade absolutely flat to the surface to prevent scoring and eventually all trace was removed.

Next job was to remove the valves from the heads. I have a choice of three valve spring compressors and it was my old standard black one that did the job. Initially the springs wouldn't compress as the split collets were stuck in the collars, a small socket placed over the top of the valve stem and an extension bar, when tapped with a mallet unstuck the collets and the valves removed. Everything was washed off with paraffin, dried and again carefully stored in the correct order..

The fourteen allen headed screws, not forgetting the four bolts that held the sump pan to the crankcase, were removed and the pan dropped down. I had remembered to drain the oil first, always a messy job, but it didn't take too much mopping up afterwards. The oil filter was removed and the pan then washed with paraffin and dried. The next day it was all packed up and along with the carbs, it was delivered to Dave at TSR Vapour Blasting at Sevenoaks, who said it should all be ready for collection in a week.

In the meantime I visited Corsa Italiana at Walton on Thames and returned with a full set of gaskets. a smart set of conical air filters for the carbs and smart braided oil lines to replace the tatty ones between timing cover and heads. I also ordered a polished aluminium alternator cover. I can't wait to start putting it all back together.

Monday, 11 November 2013

TOPS OFF

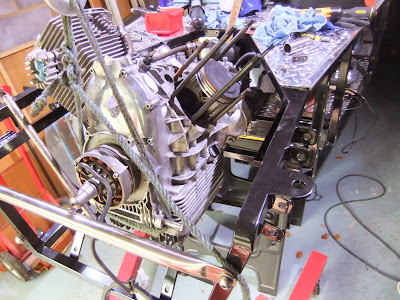

I feel that on this posting I will more than make up for not having my camera available for the last one. Firstly there follows a couple of pics showing off the shiny crankcase and gearbox.

Now it was time to remove the heads and cylinders and the first difficulty appeared, the side chassis rails fouled access to the spark plugs and it would be necessary to remove these to get at one of the head nuts that lay beneath the spark plug. On the left side I could just slide in the plug socket and using the 1/2 in drive with a spanner I was able to loosen and then remove the plug. On the right side this wasn't possible and the engine would have to be tilted up at the front to access the plug.

A socket applied to the alternator securing nut allowed me to turn the

engine over so that the relevant valves were in the closed position before loosening the head nuts.

I could now remove all the head nuts on the left side, one of which was an allen key headed nut that was hidden under a really tight cap, both of which took some serious shifting.

The rocker gear and push rods were lifted out and placed in an orderly manner on my bench. I decided to loosen all the accessible nuts on the right side before tilting the engine, so that I could safely use maximum leverage on the stubborn nuts. The engine crane was again deployed and with the weight of the engine taken, the front bolt was removed and the engine tilted just enough to remove the plug and nut from the right side. When it was time to lift off both heads and cylinders I realised that if I hadn't have tilted the engine I would not have been able to have got them off as they would also have fouled the chassis side rails, all worked out well in the end.

These items were laid out on my work bench, to await valve removal and de-oiling, but on initial inspection,the inside of the cylinders and the pistons looked to be score free and in good health.

With both pistons now exposed the engine was then gently lowered and re secured in the chassis. Next job is to drain the oil from the sump and then remove the sump cover, which will, along with the heads, cylinders and carbs be taken for professional cleaning, but that's enough for today.

Now it was time to remove the heads and cylinders and the first difficulty appeared, the side chassis rails fouled access to the spark plugs and it would be necessary to remove these to get at one of the head nuts that lay beneath the spark plug. On the left side I could just slide in the plug socket and using the 1/2 in drive with a spanner I was able to loosen and then remove the plug. On the right side this wasn't possible and the engine would have to be tilted up at the front to access the plug.

I could now remove all the head nuts on the left side, one of which was an allen key headed nut that was hidden under a really tight cap, both of which took some serious shifting.

The rocker gear and push rods were lifted out and placed in an orderly manner on my bench. I decided to loosen all the accessible nuts on the right side before tilting the engine, so that I could safely use maximum leverage on the stubborn nuts. The engine crane was again deployed and with the weight of the engine taken, the front bolt was removed and the engine tilted just enough to remove the plug and nut from the right side. When it was time to lift off both heads and cylinders I realised that if I hadn't have tilted the engine I would not have been able to have got them off as they would also have fouled the chassis side rails, all worked out well in the end.

These items were laid out on my work bench, to await valve removal and de-oiling, but on initial inspection,the inside of the cylinders and the pistons looked to be score free and in good health.

With both pistons now exposed the engine was then gently lowered and re secured in the chassis. Next job is to drain the oil from the sump and then remove the sump cover, which will, along with the heads, cylinders and carbs be taken for professional cleaning, but that's enough for today.

Saturday, 9 November 2013

THE SHINING 2

I'm useless! In my keenness to get out to the garage and get to work I keep forgetting to take the camera, so apologises no photos of this bit.

I decided it was time to clean up the crankcase and gearbox and the best way to do this was to haul the engine out off the chassis and rest it on my workmate. I plugged all the open orifices to prevent dirt getting into the engine and went to work with my electric drill, driven assortment of wire brushes, within a few hours work the old bubbled paint and crud was removed. My Dremel, with a variety of small brushes got into all of the nooks and crannies and I now have a shiny engine.

I lifted the engine down to ground level and liberally sprayed it with water soluble de-greaser which I brushed vigorously before hosing it off. I dried the engine using the compressor air line and then lifted it back into the chassis. My £130 engine lift is definitely proving to be one of my better cheap purchases.

I will soon remove the heads, cylinders, and sump and together with the carbs I will take them to www.tsrvapourblasting.co.uk in Sevenoaks, for cleaning. They recommend, ACF-50 a compound which is used in the aviation industry to prevent corrosion, this is apparently ideal for keeping that just blasted look on aluminium cases and I will be using this to hopefully keep the engine sparkling.

I decided it was time to clean up the crankcase and gearbox and the best way to do this was to haul the engine out off the chassis and rest it on my workmate. I plugged all the open orifices to prevent dirt getting into the engine and went to work with my electric drill, driven assortment of wire brushes, within a few hours work the old bubbled paint and crud was removed. My Dremel, with a variety of small brushes got into all of the nooks and crannies and I now have a shiny engine.

I lifted the engine down to ground level and liberally sprayed it with water soluble de-greaser which I brushed vigorously before hosing it off. I dried the engine using the compressor air line and then lifted it back into the chassis. My £130 engine lift is definitely proving to be one of my better cheap purchases.

I will soon remove the heads, cylinders, and sump and together with the carbs I will take them to www.tsrvapourblasting.co.uk in Sevenoaks, for cleaning. They recommend, ACF-50 a compound which is used in the aviation industry to prevent corrosion, this is apparently ideal for keeping that just blasted look on aluminium cases and I will be using this to hopefully keep the engine sparkling.

Friday, 25 October 2013

THE SHINING

I love to polish, sad person that I am, I liked to keep my canal boat nice and shiny and now I have plenty of opportunity to satisfy my craving.

I have devised a plan in respect of making my Moto Guzzi engine look presentable. The rocker covers are already polished, although they don't look like it, but the left hand one has now been brought back to a respectable shine, but still more work required. My WorkMate mounted polishing wheel did the hard work and the photos show the comparison between the two covers.

The front chain cover is sand casted and had been painted over as is the rest of the engine, but as it is proudly on display I thought I would try and polish it. I started with the angle grinder and electric drill with abrasive flap wheels, these removed the paint and much of the casting roughness. Hand rubbing with 80 grade sandpaper followed by 120 and a fine pointed mini grind stone on my Dremel in the corners, got it fairly smooth. Emery paper was next, using various grades, down to 600 before my drill mounted polishing brushes took over. The photo was taken after a trial polish and I can start to see my reflection, but it's hard work and I ended with sore thumb and fingers tips, but worth it. The masking tape is wrapped around the alternator to keep the dust out of it, having removed the black plastic cover. fortunately a polished aluminium one is available and that's a must.

For the rest of the engine, the deeply finned cylinders and head, I will remove and send away, along with the carburetters for vapour blasting, there is a company in Sevenoaks that specializes in this work. As for the rest of the crankcase and gearbox, I don't want or need to strip out the internals so vapour blasting is not an option, so I will wire brush the crud off and simply respray with aerosol engine paint.

I've had another couple of hours polishing the chain cover and I'm pretty happy with it now, although I'm equally sure I will continually go back and polish it. I think the above photo does show the improvement and the other picture shows the tools involved.

I have devised a plan in respect of making my Moto Guzzi engine look presentable. The rocker covers are already polished, although they don't look like it, but the left hand one has now been brought back to a respectable shine, but still more work required. My WorkMate mounted polishing wheel did the hard work and the photos show the comparison between the two covers.

The front chain cover is sand casted and had been painted over as is the rest of the engine, but as it is proudly on display I thought I would try and polish it. I started with the angle grinder and electric drill with abrasive flap wheels, these removed the paint and much of the casting roughness. Hand rubbing with 80 grade sandpaper followed by 120 and a fine pointed mini grind stone on my Dremel in the corners, got it fairly smooth. Emery paper was next, using various grades, down to 600 before my drill mounted polishing brushes took over. The photo was taken after a trial polish and I can start to see my reflection, but it's hard work and I ended with sore thumb and fingers tips, but worth it. The masking tape is wrapped around the alternator to keep the dust out of it, having removed the black plastic cover. fortunately a polished aluminium one is available and that's a must.

For the rest of the engine, the deeply finned cylinders and head, I will remove and send away, along with the carburetters for vapour blasting, there is a company in Sevenoaks that specializes in this work. As for the rest of the crankcase and gearbox, I don't want or need to strip out the internals so vapour blasting is not an option, so I will wire brush the crud off and simply respray with aerosol engine paint.

I've had another couple of hours polishing the chain cover and I'm pretty happy with it now, although I'm equally sure I will continually go back and polish it. I think the above photo does show the improvement and the other picture shows the tools involved.

Wednesday, 16 October 2013

WHEELIE TYRED

My local tyre supplier did me proud, £10 to remove the old tyre and fit and balance the new one, maybe that was because they were interested in what I was doing and asked that I drop by and show them the finished car in due course.

Back in my garage, I greased the final drives splined cog that connects to the wheel and rolled the wheel under the chassis. As the car is on trestles it's quiet a long way up from the ground to the final drive so I passed a strap over the top frame rail and down and around the rim of the wheel, as I shortened the strap it pulled the wheel up to the right level and with a bit of jiggling the wheel connected to the drive box.

The axle rod was also greased, passed through the hole in the swing arm, on through the brake back plate and into the wheel. A tap with the rubber mallet had the other end of the rod protruding out of the drive box awaiting its big domed nut. Everything tightened up and job done.

However the back plate will eventually be replaced with a new one designed to take not only the main brake caliper but a handbrake caliper.

Back in my garage, I greased the final drives splined cog that connects to the wheel and rolled the wheel under the chassis. As the car is on trestles it's quiet a long way up from the ground to the final drive so I passed a strap over the top frame rail and down and around the rim of the wheel, as I shortened the strap it pulled the wheel up to the right level and with a bit of jiggling the wheel connected to the drive box.

The axle rod was also greased, passed through the hole in the swing arm, on through the brake back plate and into the wheel. A tap with the rubber mallet had the other end of the rod protruding out of the drive box awaiting its big domed nut. Everything tightened up and job done.

However the back plate will eventually be replaced with a new one designed to take not only the main brake caliper but a handbrake caliper.

Monday, 14 October 2013

IT FITS

What service, the day after the order being placed, the tyre ordered from Longstone Classic Tyres was delivered

on Thursday. Complete with inner tube and rim tape brilliant. It is much slimmer than the Bridgestone Battleaxe bike tyre, but with the flat profile more rubber will actually be in contact with the tarmac. Just need

to get it all down to the fitter sometime and then I will Ebay the old, but

good condition Bridgestone bike tyre

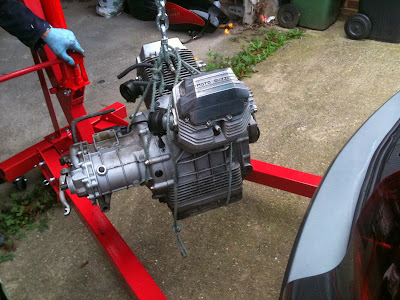

Early last Friday morning the crane was unloaded from the car and bolted back together again and the engine was easily lifted out of the car and deposited in the front of the garage. There would be no time to do anything more until Monday, but that would come around soon enough.

First job on Monday was to suspend the engine over the oil tray and give it a good wash with paraffin, a following wipe down, showed that like the rear wheel hub, there are areas where the paint has blistered off, mainly on the crank case, cylinder and head. I will have to devise a plan, as sadly it is not presentable in its existing state, but plenty of time for that.

What I did next was to trial fit the engine to the chassis. The crane gently lowered the engine into place and the front bolt slipped in easily, a little lower and the rear bolt holes were lined up. The right hand hole in the chassis had to be opened up a tad with a file before the bolt could be persuaded to go all the way through, IT FITS hooray. The bike bolts are too long, but I have checked that 150 and 220 mm long x 12mm high tensile bolts are available and when I know what other bolts I will need for the front suspension, I will order these. In the meantime the engine can stay there whilst other jobs are attended to,

Early last Friday morning the crane was unloaded from the car and bolted back together again and the engine was easily lifted out of the car and deposited in the front of the garage. There would be no time to do anything more until Monday, but that would come around soon enough.

First job on Monday was to suspend the engine over the oil tray and give it a good wash with paraffin, a following wipe down, showed that like the rear wheel hub, there are areas where the paint has blistered off, mainly on the crank case, cylinder and head. I will have to devise a plan, as sadly it is not presentable in its existing state, but plenty of time for that.

What I did next was to trial fit the engine to the chassis. The crane gently lowered the engine into place and the front bolt slipped in easily, a little lower and the rear bolt holes were lined up. The right hand hole in the chassis had to be opened up a tad with a file before the bolt could be persuaded to go all the way through, IT FITS hooray. The bike bolts are too long, but I have checked that 150 and 220 mm long x 12mm high tensile bolts are available and when I know what other bolts I will need for the front suspension, I will order these. In the meantime the engine can stay there whilst other jobs are attended to,

Friday, 11 October 2013

I LOVE IT WHEN A PLAN COMES TOGETHER

With only a bit of jangling the hoist was transferred to Reigate where I immediately reassembled it. I had given the job of removing the engine from the bike frame some considerable thought, the workshop manual says that a special frame should be placed under the engine to support it, I didn't have one of those, but four piles of three bricks and a plank of wood was half an inch higher than the underside of the sump.

With Jacquie on hand to steady things and to take photos the crane was positioned over the rear of the bike and after passing a rope twice around the frame the jack handle was pumped and the whole bike lifted just sufficiently to build the brick and wood platform under the sump. The bike was lowered and the platform took the weight of the bike. There was only two long engine bolts and four allen screws to be undone and after the bolts had been pushed out theoretically the engine was free, but the bottom frame rails needed to be persuaded to part company with the main frame and a few clouts with my hide mallet did the job.

After some vigorous pumping the bike separated from the engine until Jacquie called out there was a couple of things still attached, the linkage between foot brake and master cylinder was quickly detached and the cable from the prop stand was also released. The rear of the bike was hoisted until it cleared the engine and then it was swung side ways and lowered. The bottom frame rails were unbolted from the engine and pulled away, to be refitted to the bike later.

The rope was secured around the engine and the crane hooked up to it, a couple of adjustments of the rope to get the engine to hang square and it was raised just enough to allow it to be swung around and rolled out to the back of the car whence it was gently lowered into the car.

The bottom rails were reattached to the main frame which would allow what little remained of the bike to stand firmly and securely on its center stand. The crane was again dismantled and stowed along side the engine in the back of the car ready for taking it all back to my home garage. I was left feeling pretty smug that my forward planning had allowed the job to go perfectly, but then again I've got to get the engine it into car yet.

With Jacquie on hand to steady things and to take photos the crane was positioned over the rear of the bike and after passing a rope twice around the frame the jack handle was pumped and the whole bike lifted just sufficiently to build the brick and wood platform under the sump. The bike was lowered and the platform took the weight of the bike. There was only two long engine bolts and four allen screws to be undone and after the bolts had been pushed out theoretically the engine was free, but the bottom frame rails needed to be persuaded to part company with the main frame and a few clouts with my hide mallet did the job.

After some vigorous pumping the bike separated from the engine until Jacquie called out there was a couple of things still attached, the linkage between foot brake and master cylinder was quickly detached and the cable from the prop stand was also released. The rear of the bike was hoisted until it cleared the engine and then it was swung side ways and lowered. The bottom frame rails were unbolted from the engine and pulled away, to be refitted to the bike later.

The rope was secured around the engine and the crane hooked up to it, a couple of adjustments of the rope to get the engine to hang square and it was raised just enough to allow it to be swung around and rolled out to the back of the car whence it was gently lowered into the car.

The bottom rails were reattached to the main frame which would allow what little remained of the bike to stand firmly and securely on its center stand. The crane was again dismantled and stowed along side the engine in the back of the car ready for taking it all back to my home garage. I was left feeling pretty smug that my forward planning had allowed the job to go perfectly, but then again I've got to get the engine it into car yet.

Subscribe to:

Comments (Atom)